Install the desired nozzle and CO-plate on the spray gun.

If not already done, configure the calibration settings.

Start the fluid pump and adjust the fluid pressure.

Start the coating system and start spraying product.

Adjust the fluid pressure for best results.

Touch the information and setup bar on the appropriate Spray Monitor faceplate.

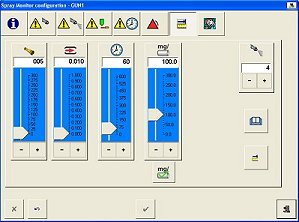

![]() Select Spray Monitor Configuration from the drop-down menu.

Select Spray Monitor Configuration from the drop-down menu.

Touch this button at the top of the Spray Monitor Configuration window.

Touch this button to start the calibration. The calibration process takes only a few seconds. When the calibration is complete, the Spray Monitor re-enables fault monitoring and returns to normal operation.

Inspect the products that were coated during the calibration. If the quality is not acceptable, inspect the gun operating pressure, CO-plate, and nozzle. Calibrate the spray monitor again if you change anything.